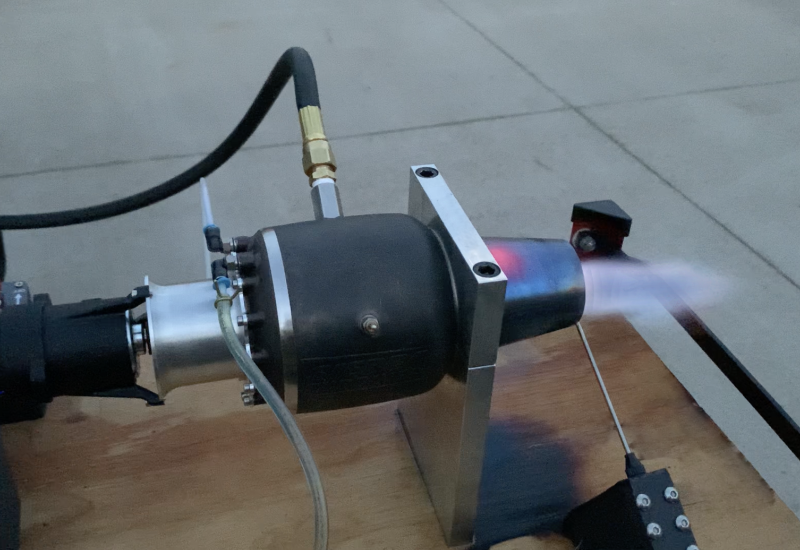

Gas Turbine Propulsion

The elegant platform for defense and commercial aerospace

> Elegant

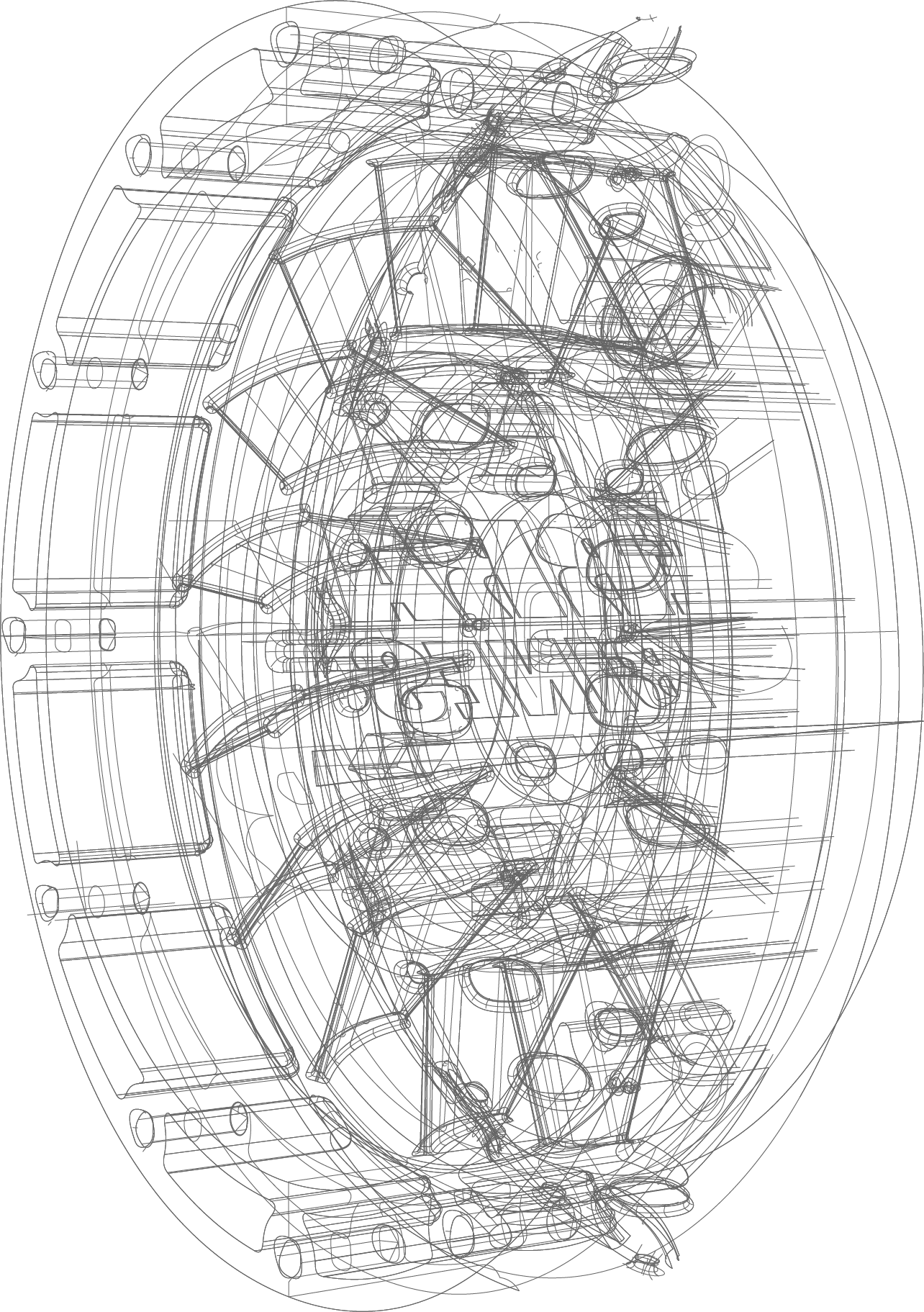

For instance our ST160 engine has only 17 parts

> Versatile

Scalable Architecture to address the growing demand for thrust

> Tough

Haynes 282 core

Sierra Turbines offers:

Replicable mass, at the speed of Defense requirements.

100% ITAR Compliant Supply Chain - Manufacturing, materials, and equipment is made in the US.

Reliability

Delivering commercial jet-engine platform features and reliability for microturbines.

Our low part-count architecture removes many points of failure and helps to improve the time between overhaul for multi-mission use.

Thrust

ST160 delivers 160N/36LBS thrust.