Metal 3D Printing: Who Needs Supports?

Support-free AM technology is proving its advantages with greater design freedom and less engineering time.

Kristin Mulherin

FEB 11, 2021

Velo3D

At a Glance:

In the metal AM process, supports in anchor parts prevent distortion.

Support structures are made of the same materials as the part and prevent distortion, but add considerable design and manufacturing constraints.

In two applications focusing on microturbines and shrouded impellers, VELO3D demonstrates how its support-less technology eliminates the need for support structures.

In metal 3D printing (or additive manufacturing) there is one dominant technology for printing industrial, production-quality parts: powder bed fusion (PBF). PBF technology is widely used to produce medical implants, gas turbines, aerospace parts and multiple other applications across the dental, energy and automotive sectors. It is the most mature and widely used technology because it can produce production-quality parts that cannot be produced by any other method. However, PBF has its challenges, one of which is the need for “supports” when printing parts using typical PBF systems.

What Are Supports?

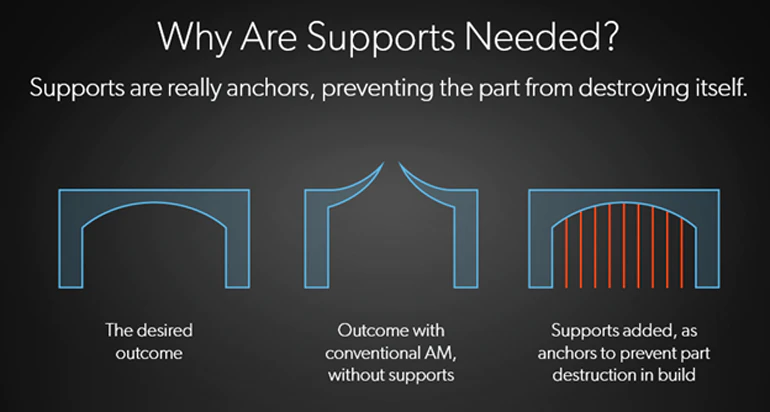

The word “support” can be misleading, especially to those who come from the polymer 3D printing space. Supports in metal 3D printing work counter-intuitively like “anchors” that hold down, rather than hold up, features within the part. This is to prevent a part from distorting from the residual stresses caused by the high processing temperatures, which will not only destroy the part but also typically cause the re-coater to crash.

Velo3D

When are Supports Typically Needed?

Not all features require supports, but many do. The features that almost always require supports in typical laser-PBF systems are overhangs, holes and channels. Considering additive manufacturing is touted to produce more complex parts with more intricate features, it can be misleading—and frankly, disappointing—to then learn that this can only be accomplished with the addition of multiple supports and counter-intuitive build configurations.

Granted, in polymer 3D printing supports this might not be as big an issue, since they can be dissolvable or easily removed. But with metal 3D printing, supports can be difficult to remove (even if they are accessible), leave defects on the surface from which they are removed, and add significant time and material costs to the overall workflow.

Overhangs

The first feature that requires support is overhangs, which is typically needed if they drop below 45 deg. from horizontal. How many features can you imagine in a typical component that meet this criterion? Often many. A demonstration of what happens as the angle dips below 45 deg. is shown below.

Protolabs

There are three solutions to this problem: reorient the part in the build chamber, redesign the part or add extensive supports. Many resort to reorienting the part in the build chamber, but this comes with its own problems. Take a circular part, such as the impeller shown in the image below.

Velo3D

Many people approach shrouded impellers like this by tipping them up at a 45-deg. angle. The problem with printing at an angle is that breaking the axisymmetry of the part leads to many issues. First, the circularity of any component that rotates is critical. When printing at an angle, this can be very easily compromised in terms of dimensional stability alone. Additionally, in the case of L-PBF 3D printing, the mechanical properties in the Z-direction can be different than in the X/Y plane due to the layer-by-layer process. So, by printing at a slant you will end up with mechanical properties that change as you go around the circle. This is especially problematic in applications where the part is exposed to high stress.

Inconsistent surface finish is another concern. The surface finish will be different at varying degrees of slant. This is not a concern if printed flat, because the variances would at least be symmetrical. Some might say that post-processing will address this, which is true—unless you have those very complex internal features so heavily touted as a selling point for metal AM. Alternatively, abrasive slurry polishing is a popular solution, but it will not address these surface finish variations without removing a lot (and often inconsistent amounts) of material.

Instead, VELO3D has developed a capability, called SupportFree technology, that angles down to a fraction of a degree and can be printed entirely without supports. So, in the case of the impeller above, it can be printed flat and without internal supports, maintaining part axisymmetry and greatly minimizing post-processing.

Holes and Channels

The second type of features that often require supports are holes and channels. It is widely accepted that L-PBF systems can only produce horizontal holes and channels around 8-10 mm in diameter before requiring supports. There are design choices that can be made to try to avoid this, but none of them are ideal. Changing channels into teardrop, elliptical or diamond shapes (per below) are the most common.

Velo3D

There are a few reasons why this would not be desirable. First and foremost, holes and channels are incorporated into designs for one primary reason: to facilitate the flow of a fluid (liquid or gas). In most cases, a circle is the most efficient shape for the flow of fluid, whereas the above shapes will certainly have a detrimental effect on fluid dynamics. Also, the top of the teardrop and corners of the diamond are serious stress concentrators—a big concern when it comes to pressurized fluids. Some might recommend filleting these corners, but this does not entirely remove the stress concentrators; it merely lessens them. And it certainly does not help the situation with flow dynamics.

Alternatively, with VELO3D SupportFree process, holes and channels with inner diameters can be produced up to 100 mm (~4 in.) in diameter. This 10-fold increase in allowable inner diameter greatly opens the design window for increasingly complex interior channels and truly allows the design to be optimized for function rather than manufacturability.

Why Does it Matter?

SupportFree gives you design freedom. The ability to print those complex geometries and intricate internal features gives the designers and engineers an easier point of entry to adopting additive manufacturing. Without it, extensive Design for Additive Manufacturing (DfAM) knowledge is required, which teaches the designer the ins and outs of the required compromises rather than the unlimited design freedom. In short, this technology gives the power to design for optimal functionality rather than manufacturability.

Real Applications

So, what kind of applications benefit the most from SupportFree? In short, optimized designs that control the flow of fluids or transfer of heat.

Great examples of this include microturbines, air foils and impellers, heat exchangers and manifolds with large inner diameters. The first application, microturbines, cannot be represented any better than by Sierra Turbine’s gas microturbines for hybrid UAV propulsion. And the second case study introduced below, Hanwha Power Systems, is a perfect representation of what can be done with shrouded impellers.

Sierra Turbines – Hybrid UAV Propulsion

Sierra Turbines used the VELO3D AM system to produce a gas microturbine that could not have been produced any other way. This microturbine enables hybrid propulsion for high payload UAVs with 40 times less maintenance, 10 times more power density and a 50% reduction in weight. By printing this part with 3D technology, the firm was able to take an assembly of 61 components and produce them as a single part.

Velo3D

From the start, Sierra Turbines realized additive manufacturing was the solution to creating a truly unique and differentiated product. The company spoke reached out to existing vendors and was told that it could produce anything so long as it had angles of 45 deg. or higher. However, when it came to the airflow through the gas turbine engine, that constraint would disrupt the flow and does not really lend itself to an efficient engine. Ultimately, Sierra Turbines found that the VELO3D platform was the only solution that did not require it to redesign its part in order to be manufactured.

How was this accomplished? The answer comes through utilizing Flow software to control the process and having the hardware that allows us to do it. From a library of pre-developed recipes, the simulation software can assign each feature a set of ideal processing conditions. Whether it is low-angle walls, vertical walls, or lattice and bulk structures throughout the part, specific processing conditions were automatically applied to mitigate feature-specific failure mechanisms and eliminate the need for extensive DfAM and specialized operator knowledge.

Velo3D