Proving Digital Twin Communications in the Desert - Full Case Study

Daniel Life

November 3, 2021

Reporting from Bonnie Claire, NV

60 miles from Las Vegas

Update: Link to an article by Swarm

Off-road racer Goliath with Swarm-based Sierra Turbines SATCOM solution mounted on the roof.

August 13, 4:53 AM - Paul Zaro rolls the race vehicle out of a car trailer. It's wheels are water jet cut steel disks that look like barbell weights, and make loading and unloading possible. They glide in a special channel mounted to the the back of the combination door/ramp.

"I don't sleep well the night before a race. I have crazy dreams about the mechanical items. It's too exciting. I'm wound up and want to get started." The race day mechanical checklist from last night get's a second run through.

The race vehicle is Goliath, a 4-wheeled, 750 horsepower, custom creation by Paul. Running on 112 octane race fuel, it's not a car or a truck. It's an elegant monster, funded out of pocket by Paul. He's the team's primary mechanic.

Goliath Stats

5:31 AM - With his full attention on Goliath, Paul doesn't notice Dave Zicovich, walk over. "You too excited to sleep again, Paul?" Zicovich is a driver for the team. That's when he's not building custom homes for Silicon Valley executives.

Together they are Paul Zaro/Zicovich Racing. Driver/navigator Jack Zicovich, is a real estate investment analyst, and Dave's son. Driver/navigator and electric bike entrepreneur, Andrew Davidge rounds out the team. Paul’s day job provides the carbon offset for 112 octane racing fuel . He fabricates and installs data center cooling systems that use water (absorption chillers) instead of traditional refrigerants, which helps to reduce energy consumption in Data centers..

The full crew shows up and together they install the wide knobby racing tires. Bonnie Claire Nevada is this year's starting point for the 550 mile Vegas to Reno race through the desert.

The race is held primarily in areas under the control of the Bureau of Land Management. Yesterday was Tech Inspection, and Goliath checked out with flying colors.

Race Stats

10:30 AM - It's go time!

Two days of racing through the desert.

At 10:30 its already 93º, UV Index of 6, and only a 2 mph wind to blow the dust around. By 3:30 the humidity will drop to 14% and the temp will 106º. Waiting for the green light, the team sits in full racing suits, helmets, and full Nomex fireproof underwear. A fabric helmet skirt and head scarves are there to catch the sweat and keep some of the dust out. Pumps push fresh air into the helmets and a small water tube offers occasional sips between adrenaline peaks.

Racers are being started with an extra time gap as there isn't enough wind to clear the fine silt dust from the start area. Radio safety checks complete, Dave and Andrew get the signal. Dave hits the accelerator trying not to rock spray the start line officials.

Goliath jumps forward with traction at all 4 wheels.

Wait, that's a half-wave antenna on Goliath!

Half-wave antenna mounted on Goliath

David Zicovich recalls, "Roger Smith texted me one time while I was at a race. I sent him back a picture of Goliath and the desert. He called me and said he had an idea. He asked me if we would put a box and an antenna on Goliath and track it with satellites. Roger also said he wanted to put sensors on Goliath and send messages to and from the vehicle. I asked what it was for."

Roger replied, "It's part of our command and control system. It's better than commercial avionics systems because it's two-way communications vs. one."

Zicovich said, "if you're looking to test something, there's no harsher environment than off-road racing other than battle. He immediately thought that was a pretty darn good idea."

‘Flight deck’ inside Goliath. Analog gauges are preferred over digital.

Much of the technology in off-road racing is analog because it can take the abuse. Digital tech is starting to appear more at races, but the preference is for old-school gauges.

For the race, the Sierra team opted for a half-wave antenna. It is approximately 1 meter long vs. the sub-1 foot quarter-wave antenna which was secured on top of the roof. A Swarm Eval kit 01 including the Swarm Tile satellite data modem was also on the roof. A Swarm data plan and a custom application developed by team Sierra provided a two-way, always-on connection.

Image at Left shows quarter-wave antenna used for early testing. Right: half-wave antenna and Swarm Eval kit.

Russ Winsper, Software Architect

"We've been working on proving out capabilities related to our version of a FADEC. We'd like each of our turbine engines to be able to communicate with us. We want to talk to them, and have them also be able to phone home. Of course, it wouldn't be via phone, it would be by satellite."

Testing goals

Building an Autonomous Engine platform

An autonomous engine platform is like an iceberg: some critical parts are visible. There are more beneath the surface. Two visible components of the platform are the turbine engine and the engine control system. The engine control system in the UAV/aerospace world is a FADEC or Full Authority Digital Engine Control. This is avionics.

A key premise of a FADEC is that it must be able to function without human control. The assumption is that the engine may not have reliable communications with a command and control system. Solving the problem of two-way communications creates the ability to have both autonomy AND control.

Sierra Turbines is applying the design principles of large scale engines to microturbines. Their vision is to develop a platform that delivers aerospace-grade performance and reliability. The secret sauce is using material science and advanced technologies to unlock performance.

The company is currently chasing two initial applications: Unmanned Aerial Vehicles, and electric power generation.

1. More power for UAVs

Commercial and military UAV users want propulsion systems with high power to weight ratios. Squeezing the most energy out of the lightest engine opens up more possibilities. Three solutions: 1. Lithium Ion batteries, 2. hybrid battery and gas, and 3. scaled up hobby engines are used to power UAVs. The quest for more amp hours per kilogram is a big deal.

High availability / reliability is a big deal, too. Downtime for battery swaps and scheduled engine maintenance can be costly. Unexpected downtime or engine failure can be catastrophic. The TBO metric, or time between overhaul is measured in hours. Actual TBO times cited by UAV engine manufacturers and even commercial jet engine companies can be substantially less in practice than advertised. Often, this is due to unanticipated downtime.

Both of these market demands excite Sierra Turbines CEO, Roger Smith.

"Scaling a commercial jet engine down to power a UAV while improving reliability is what we're all about."

2. Cleaner power for electricity

Environmental, Social and Governance measurement (ESG), and it's impact on the cost of capital and credit isn't going away any time soon. Investors and lenders are tying sustainability to risk. This is motivating power generation companies to find greener solutions.

Stationary power can be grouped into remote power, backup power, and utility thermal power generation or power plants. The low production cost variability of renewables is encouraging utility operators to balance and cycle between fossil fuels and renewables. Operations that were all about continuous power production, are dialing back fossil-fueled generation until demand peaks.

Gas turbines are being used to address load management for power generation. Sierra’s new designs include flexible turbine arrays.

Utilities describe energy generated as base load, intermediate or load-following, and peaking electricity. Gas turbines can play any of these roles in power generation. Their ability to ramp up and down quickly, plus new micro and mini turbine designs can operate more efficiently at lower load levels.

"Aero-derivative turbines are very flexible, especially with the designs possible through additive manufacturing and advanced materials,"

says David Laudermilch, head of Design Engineering with Sierra.

"These aren't the large frame turbines, or even the aero turbines from recent years. We're looking at autonomous engines in arrays, that can tell us when they need something."

The case for digital twins on the platform

Digital Twins are real devices that have a representational double in digital form. In some cases, the twin can control and interact with the real device, in others it reports the status of sensors on or around it. This is the industrial side of IoT or IIoT.

Common models of implementing digital twins start with the real device and sensors sending data to a nearby gateway. The gateway translates and/or aggregates the sensor data and forwards it to a cloud. Once in the cloud, analytics, reporting, and APIs interact with the data.

The digital twin gets its 'life' from applications that display status and levers and switches [buttons]. A press of a button has the potential to change both an animation or image on the digital version of the twin. It can also interact with the real device.

This isn't the model envisioned by Sierra Turbines.

"We could push data to a cloud in the same way commercial turbine engine manufacturers do. We choose not to. We are actually instructing our controller to use machine learning and edge compute to process the data on the device itself, "

Smith said.

"The big deal about that is the efficiency, but also the security. If we don't need to transmit certain data, it can't be intercepted.

Two-way (communication) is very important as our application is command and control. In our case, we don't really transfer a lot of data. We do pass a lot of messages back and forth. The information we want is actually generated on the device, so we send relatively small messages across the network."

Image: Sierra Turbines

A little background on digital twins in use.

Turbine jet engines produced by the big names in the industry all have digital twins. This is especially useful for command and control. The Sierra team discovered that current battery, hybrid-electric, and microturbine UAV solutions do not offer digital twins. This pain point, coupled with a lack of insights other than service hours, creates significant UAV fleet management issues.

The electrical power generation/utility industry has been using digital twins and Industrial IoT for many years. The ability to control, gather analytics, and fine tune turbine performance is a baseline requirement.

According to Roger Smith, "Building a better solution for both of these industries is significant and worthy. Our testing helps us prove the concept of global, two-way connectivity for digital twins."

Enterprise reliability

Smith continued,

"Reliability. Three thousand hours between overhaul. This is a fundamental challenge of the aviation industry today. We'll have a lot more to say about this topic in the future."

Track

While the location of a stationery asset may be less important, with flying objects, it becomes critical. The Sierra Turbines team wanted to test this essential feature. Russ Winsper:

"For our platform, the key is two-way communications for status and control. And in the case of a moving object, tracking it. Not just knowing where it is, but tracking it. We were testing to get field data,"

2. Control

Winsper continued, "We have more testing to do related to control. A drastic example would involve turning off a turbine engine in a drone. If you did that, it would crash, which we don't want to have happen. What you might want is the ability to reduce the turbine operating temperature. It would also be good to have some control of some of the pumps or actuators. If you were generating electricity with a stationery turbine, starting, stopping, making adjustments would be a natural." The Sierra team is looking forward to expanding control capabilities on their product roadmap.

3. Predict

Operating hours are the primary piece of data used to determine whether a turbine engine needs an overhaul. Maintenance technicians also often use observation. For example, it is common to take advantage of unrelated repair windows to check engines over. Fleet managers tend to follow manufacturer maintenance recommendations. They combine with their own field data to set service intervals. It can be tricky to balance the two. Every piece in the formula costs money: spares, downtime, overhaul labor and parts. The cost of equipment failure in the field is expensive, too. For this reason, preemptive engine overhauls are common.

Avoiding unnecessary overhauls, and finding engine problems between service intervals are key problems Sierra wants to solve.

Russ Winsper

"If you can talk to the device, you know what the status is. You know, if it's starting to run hot. That is an indicator that it's going to need an overhaul shortly."

"In an electric generator, you might have a target, say twenty five or seventy five megawatts. If one of the generators is operating at only 10 megawatts, things are not looking so good. It might be time to do an overhaul. So there's a possibility of looking at the output for that in both cases. We want our Digital Twin to have solid communications with the real-world device."

49 years of Digital Twin data analysis

It started at Apple

Both Russ and Roger worked at Apple. Combined they have 49 years of enterprise software development in hardware communications. In talking with them, they recounted the many similarities in their work at Apple and Sierra Turbines.

1. Their Concept of Digital Twin began with computers

"Digital Twin has been most of my career. Let's say you have a device out in the field. A Mac was my typical case. Every product: Microsoft, Windows, Apple, they all report back collected statistics. That data came to Russ and me."

[I'm guessing in large bucket fulls.]

2. Big Data and Trend Spotting before it was a thing

"It would be like 350 million log files. We wrote software to identify patterns, and patterns within patterns. Log analytics. We'd find categories of issues that we needed to look at because it was happening say one or more times a day. In the case of a lack of information, it could be something that didn't get reported, or the computer wasn't turned on. We had to perform analytics to do our job of writing software. "

The concepts of efficiency and minimalism are common to Roger and Russ. "We can't shoot 350 million packets across the satellite network, and we would never want to do that. We send the anomalies. Instead of a server doing the processing, we use edge compute on the device. If it identifies a handful of items with the same signature, that could represent a problem," said Smith.

Talking AND listening to satellites

The big deal behind two-way SATCOMs

Image Courtesy of Swarm: https://www.swarm.space

Sierra Turbines picked Swarm because of their two-way satellite communications network. A second reason is the dual channel that includes GPS built in. The Sierra FADEC transmits a GPS signal of its location (plus other data) at a minimum of every 15 minutes. It can do on-demand intervals closer to 5 minutes.

Swarms’ seamless 2-way connectivity represents game changing capability for UAVs.

Add the GPS positioning data to the mix, and it almost becomes a separate product for Sierra Turbines. In talking with Russ and Roger, they are platform focused, for now.

Safety in commercial aviation

ACARS, or the Aircraft Communications, Addressing and Reporting System began in 1978. This replaced certain types of human-based radio communications over VHF and HF with sensor driven, automated messages. It uses a combination of satellite and radio channels. Its primary uses are for air traffic control, airline services, and airline administration. Because it is automated, its data gets used when planes go missing or have major issues.

MH 370: 1-way and every 60 minutes isn't enough

Malaysia Airlines Flight 370 from Kuala Lumpur to Beijing on March 8th, 2014 is still missing. 239 people were on the flight. It was flying over the South China Sea. The last contact with the plane was by SDU, or satellite data unit which logged onto Inmarsat's network a few minutes after disappearing from radar. One theory is that the plane turned south toward the Indian Ocean and continued until it ran out of fuel.

The most expensive search operation in aviation history begin 4 hours after it last reported into air traffic control. The precise location was never transmitted by the plane. Search efforts began in a 23 mile radius, which became a 120 mile radius.

Search areas for flight MH 370

At one point, US sources suggested that engine manufacturer Rolls Royce had gotten engine health status reports every 60 minutes. They also stated that the reports continued for four hours after the plane's transponder stopped transmitting. The initial surface search area grew to 230,000 square miles as MH 370's path and location could not be determined.

On April 28th, the surface search effort was suspended. An international underwater search continued through January 2017.

MH 370 made a strong impression on Roger. He’s thought about it a lot:

"The problem the searchers were faced with was determining the path when the plane had been flying around for 5 or 6 hours at 500 miles per hour.

Imagine if three things were different:

1. The engine reported in every 15 minutes - cutting the search area by almost 75%.

2. The SDU transmitting GPS coordinates - reducing the guesswork of direction and location,

3. Two-way communications - additional ACARS messaging from the plane indicating what was happening onboard might have been possible.

MH 370 is a motivator for us to lock in these capabilities on our platform."

Why not cellular

Sierra Turbines spoke with cellular carriers before choosing Swarm. Meshing a startup with an enterprise turned out to be a challenge. The team received lots of inbound requests to meet and offers of support.

"Companies were all over us. We told them we knew what we were doing, please send us some modems and accounts to get things going. That has never happened," recounts Roger.

There were other challenges with cellular. For example, coverage for data is less than voice, and even voice is not global.

Russ Winsper:

"If you're in the middle of the desert, you don't have a cellular connection for the most part. We tried it. With international applications, the issue becomes frequency bands."

Benefits of two-way communication

One-way communications resembles smoke signals. A message is transmitted up into the air. Another location sees it and records it. In this scenario, being connected is enough. In the world of satellites, a message is transmitted up to the satellite, and the satellite sends the message to a ground station. It is then delivered to the end client by the internet.

Sierra Turbine's use of the Swarm satellite network is two-way. They report status every 15 minutes like one-way users. But they also can query the network outside of that cycle, on demand. In fact they do not need to broadcast on a regular schedule, which also does not tie up network resources. They've figured out how to cut the message delivery and turnaround time with their own enterprise software application.

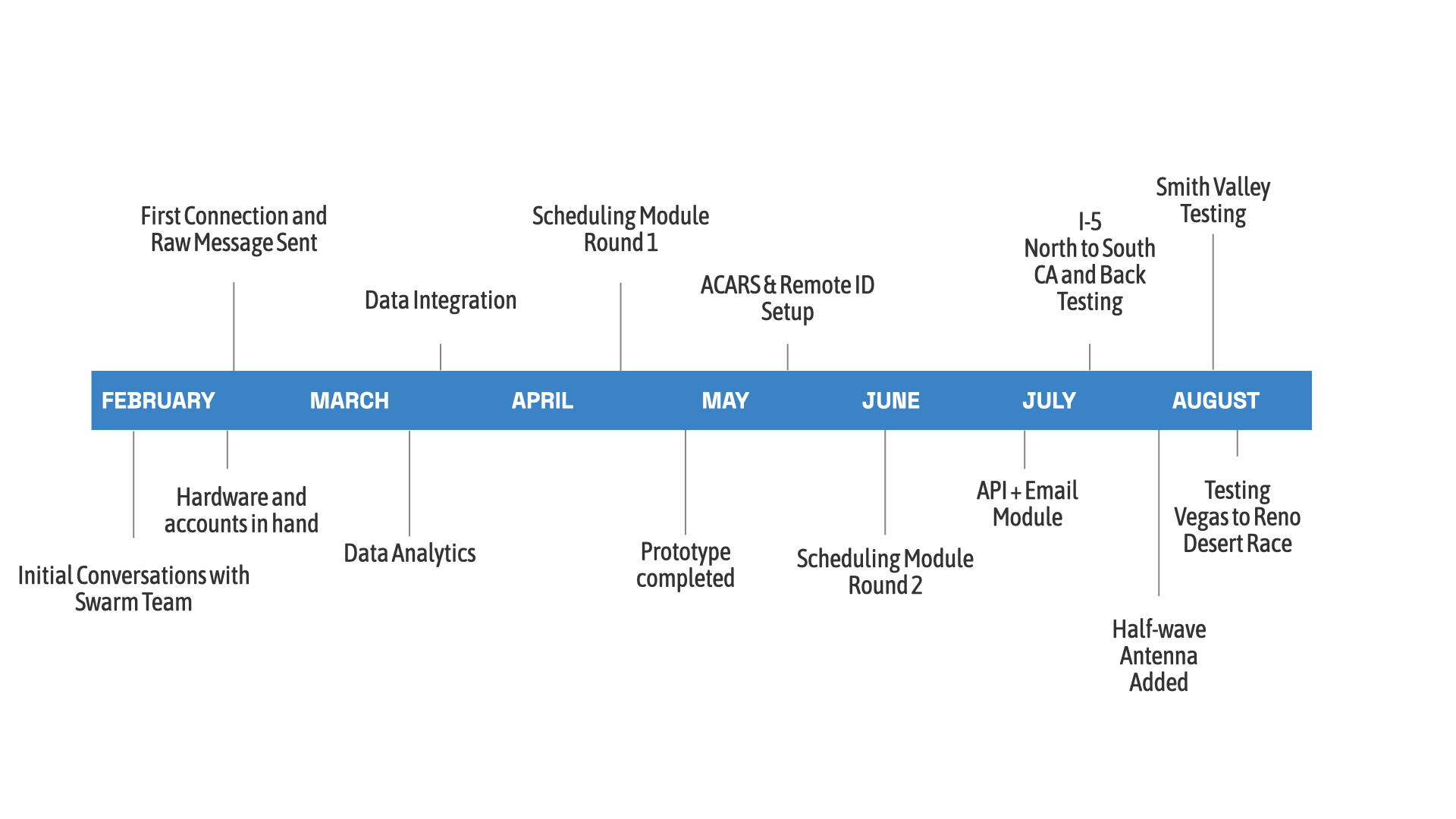

Idea to enterprise application in 6 months

Russ and Roger led the application development and worked with the Swarm team.

Roger: "The timeline was epic! From March to August, it was constant development, integration, flashing, and testing with different antennas. The moment they had sample hardware for developers, we had them. That started us digging into their documentation and banging on their network. The tile modem connected to the satellite, no problem. Now it was on us to figure out how to send and receive messages."

Russ: "I was impressed with how easy was to actually get it set up and talk to the satellite. When both Roger and I got the development kits it took, five minutes and all of a sudden we were we talking to the satellite. Basically it was, 'Wow, this is really easy and it's kind of neat.' We just happened to have a synergy with Swarm. It helped that we had relationships with some of the engineers who had also worked at Apple. We knew each others' capabilities, so there was a great deal of trust both directions."

During the development, there were firmware iterations. This meant code changes with each firmware release. The Sierra team stayed with an earlier development unit to avoid some rewrites. In reality, adapting and re-testing had to happen with the final release before testing on I-5 and the Vegas to Reno race.

The pair put the Swarm network through its paces. Their goal was to verify if Swarm could deliver and enterprise capable network. Part of that was applying their knowledge of GNSS or or Global Navigation Satellite Systems. GNSS falls in the category of Position, Navigation, and Timing Systems. The US GPS is a specific example of a GNSS. There are others.

Image: Sierra Turbines

A little background

The Swarm tile modem has two data links. One reads the GNSS location, which is a one-way signal. The other link provides two-way connectivity. The built-in GNSS helps identify the location of the modem and the surrounding device or solution connected to it. Swarms' GNSS provides concurrent reception of up to 3 GNSS: GPS (US), Galileo (Europe), GLONASS (Russia), and BeiDou (China). The benefit of multi-constellation positioning is much higher accuracy. For high-speed flying objects, being off by 10 feet can be disastrous.

Roger: "The DOD only uses the US GPS system as there are special military channels on the GPS satellites. However, they can and have been hacked, and the Military is always on the lookout for alternatives. GPS can have some value in certain situations. Remember, this is not a buoy out in the ocean. Our test was high-speed, 100 miles an hour, enterprise-grade tracking."

Sierra Turbines' two-way enterprise SATCOM solution

Scheduling algorithm

Getting messages to and from Swarm satellites uses two different paths. Sending data to the satellite is direct, as the satellite is easily able to 'hear' the modem. Receiving messages means the modem must 'listen' for the satellite, which is more difficult. For a command and control application, messages flow from the digital twin over the internet to a ground station. The ground station schedules the message to send to a specific satellite during a specific time window. In some cases, messages will time out. This is often due to a satellite passing at a low elevation to the horizon, and the modem doesn't 'hear' it. If a ground station transmits to more than one satellite, messages can duplicate.

Roger: "We've seen duplicate packets, so we had to develop our own algorithms to address that. Swarm has their own sophisticated scheduling algorithms, but they aren't working with the deliverability of ethernet.

This is space messaging.

They don't just randomly send data to a satellite or else they'd end up having too many messages. This is referred to as buffer bloat; when there's too many packets waiting to either time out or be sent. We worked closely with Swarm to understand how messages are scheduled and wrote a lot of software to optimize the two-way communication."

Predictive message delivery

Using ephemeris data to minimize buffer bloat .

To build their own scheduling algorithm, Sierra Turbines accessed Swarm's APIs to pull in ephemeris data. Ephemeris tells you a satellite or celestial object's position, [X, Y and Z], and velocity, over time. Knowing where satellites are, allows you to better predict when there will be a window to communicate with them. It is also important to understand that satellite orbital track can change. This happens when satellites are being 'moved' from a launch orbital track to their destination track. This affects timings.

Because the Swarm constellation is in Low Earth Orbit (LEO about 500km above Earth), their satellites take about 90 minutes to circle the earth.

Geostationary (GEO) satellites orbit the earth in 24 hours. Situated 35,786 km above the earth, they see the Earth as if it is not rotating because they are in sync with it.

Image Courtesy of Swarm: https://www.swarm.space

Swarm also provides an application called the Swarm Satellite Pass Predictor. Sierra Turbines also references this data within its' software.

Because Swarm's constellation is growing, not all of its satellites have 90 minute orbits yet. Some might be traveling faster, for example 92, 93, or 96 minutes. This adds a layer of complexity to predicting communication windows.

Roger: "To minimize, how many packets we queue up and reduce the risk of messages timing out, we reference the orbital data and then generate requests to the Swarm servers. That's how we can get the round trip time down to about five minutes. This is important for our enterprise application."

Creative analysis

Sierra Turbines isn't the only customer on Swarm's network. Russ and Roger knew that other network users would be looking to have packets delivered in the same access window. This meant their own scheduling algorithm would need to adapt to friendly message competition. They turned to something they both had used on hundreds of millions of messages: log analytics.

Roger:

"Our analysis and our software had to deal with complex scenarios vs. doing messaging randomly. For example, imagine you just missed the beginning of an overpass window. What if, you could send your message request 10 minutes before the satellite pass?

Another example: What if you have a minimal overhead pass of 10 minutes? If you send it at X time, what is the probability of your device receiving it very quickly after you send it?

And being experienced software engineers, we of course said, ‘OK, how far can we take this?’ So we crafted enterprise grade software based on analytics, our own unique algorithm, which helps us deliver on the promise of a connected digital twin."

Image Courtesy of EVDC https://evdc.esa.int/

Working with super heroes.

Finding excellence in your own Silicon Valley.

Roger and Russ aren’t shy about putting a plug in for worthy Bay Area players:

"We were pleased to find another Silicon Valley local company with seasoned engineers doing incredible work. Our team suffered through lengthy sales conversations, endless meetings, and high initial product quotas from US and non-US companies. Not convinced. These huge companies assigned us project managers, and wasted our time asking us to explain what we wanted to do.

When we found Swarm, we were like, 'Wow! Here's someone in our own backyard whose way of working truly supports innovation.'"

We worked directly with their engineering team. In 3 months we achieved a prototype, and iterated to an enterprise application in 6 months. The incumbent solution providers could not do this."

Russ Winsper: "We know the caliber of the team. It’s great. I had a chance to speak with one of their RF engineers recently. I noticed an article he'd written. He is one of the best RF people I've ever spoken to. They've got incredible talent."

What would you say is their superhero talent?

Russ:

"Fast, and nimble like Spiderman. Their web is the satellite network.”

Roger:

"DC or Marvel?”

[Your choice.]

“I would say Iron Man. He can fly in space and communicate technopathically with satellites. As Iron Man, Swarm's super talent is vertical integration."

What do you admire about Swarm overall?

Russ:

"I absolutely admire what they've done. 90+ satellites, soon 150 up in space in their preassigned orbit. It's amazing to me."

Roger:

"They get enterprise developers."

What was it like working with Swarm?

Russ:

"The ability to get answers and information very quickly was great. When there was a new firmware release or updated tile, they would explain, 'this is what's new and how we're going to use it.' "

Roger:

"Whenever I asked about the date for a feature release, they'd say, 'Working on that. You want one now?' "

Testing the Prototype on Interstate 5

Quarter wave through the sun roof

Before going to the desert, the Sierra Turbines development team decided to do a Northern California to Southern California pilot. Roger was not ready to permanently mount an antenna to his SUV. Instead, they secured the 1' long antenna inside the vehicle and let it poke out through the open sunroof. Roger drove to Los Angeles while Russ tracked the vehicle.

Russ: "When Roger was driving down I-5, I was tracking and watching the data. In the process, we got a temperature warning. The message was that the modems' temp was over 30º Celsius (86º F). The modem was directly in the sun. We knew the modem would still work fine at that temperature, we simply inserted a number to ensure we received a warning message. As another test, we reported every time the temperature went up by five degrees Celsius. This would trigger a warning message. We only ever got one, so it never got above 35º Celsius (95º F). It all performed well."

Voice vs. Data Coverage

Roger: "People don't often think about the interesting subtlety of the difference between data and voice networks. You can drive along I-5 and get very spotty voice coverage and actually have zero data coverage. We tested our solution using Swarm's technology all up and down I-5 and we were very happy.”

Results

To date, Sierra Turbines has completed about 2000 kilometers of enterprise level testing. A combination of road tests on freeways, city streets, and remote areas have served as test locations. The team did a big push with testing in rural California and Nevada before going to the desert. A large portion of the testing included areas outside cellular coverage. Including Smith Valley, Nevada

Smith Valley, Nevada - 122.5 square miles. Population 1,627. Elevation 4,790 feet.

Roger:

"It's really a testament – this is an enterprise application. It's got to work where there's no cell coverage."

When cell coverage is available in the desert, it’s natural to get curious about what’s nearby.

Tracking mobile assets at 100 miles per hour

August 13th, 12:58 PM - Pit Stop 1 of the Vegas to Reno Race.

Andrew Davidge and Jack Zicovich have been racing for about 2 and a half hours. The sun is hot. The silt dust hangs in the air from the vehicles ahead. Boulders, smaller rocks, scrub brush, and 70+ year-old saguaro cactus test the duos' ability to go fast and avoid obstacles. Because they are in race mode, only the biggest of problems command their attention.

Jack Zicovich: "We made it to Pit 1, and found a few issues with the car. They were OK to drive on. After we left Pit 1, our Lowrance system froze. It wasn't tracking us. It's not a newer model. Andrew hit reset. I was trying to help him get back to the right screen, and driving without a map. We came up on a corner at 75 or 80 mph, but I had no idea it was a 90º turn.

We start to pivot into the turn and I prepare to counter steer. At precisely the wrong moment, all 4 wheels line up. They catch the dirt and the vehicle just flips over. You don't really spin around on a corner like a go kart or car on tarmac. We weren't going to finish the race."

After Jack and Andrew were picked up by the track safety team and back within cell coverage, David Zicovich phoned his wife. He led with, "Our son Jack is OK, but there was an accident."

Jack Zicovich: "Andrew made a good observation that we'd probably be more sore to have run the whole race. You're just getting your ass kicked out there because it's so brutal. The road is so rough. There were a few times where I was under-braking, and going into a corner, the steering wheel would get ripped out of my hands. It was 3 hours of hard work."

When Goliath tumbled over, the Swarm equipment on top took a beating. The antenna was mostly fine, and the development kit box had gotten loose. It was cracked, and parts had moved around inside. Data collection stopped, with the last message 6 minutes before the rollover. It included Jack and Andrew's GPS coordinates.

Russ Winsper:

"We were following Goliath and getting data back and forth throughout the race. When they stopped at Pit 1, we could tell. When the car stopped running, we knew right where it was. We just didn't have cell coverage to call and find out how they were."

Roger Smith:

"At that point, we didn't care about the testing. We had to find out if Jack and Andrew were OK. We had to wait, and the 40 minutes seemed like a very long time."

While the race was in progress, Goliath sent email messages to the remote team.

Proof points: What was validated through the data

In talking to Roger and Russ about the results, it was clear they see testing as a regular part of the process. When asked if they’d do it off-road in the future, Roger smiled and quickly answered, “NORRA Mexican 1000. But first we have to get Goliath some additional sponsorship.”

Swarm + SpaceX

Both Roger and Russ were positive about the recent acquisition of Swarm by SpaceX.

"We look forward to seeing how SpaceX's infrastructure will accelerate Swarms' build out,"

explained Roger.

Russ: "I see a lot of great synergy between the two companies. We’re excited for what the future may hold."